In a time of record feed prices it is essential that feed wastage be minimised. It is estimated that 10% of feed delivered is wasted on the average farm (AHDB, n.d.). Feed wastage can be considered in two major components — mechanical and biological. Feed is often wasted from the point of delivery to the passage of faeces.

This article details some of the areas where this wastage occurs at the farm level and focuses on simple management practices that veterinarians can discuss with their clients to reduce these losses. Reducing feed wastage by half would make the difference between profit and loss on many farms. With health costs being about 5% of total costs, the wasted feed could account for twice the health costs. Halving feed costs means health costs are ‘free’!

Where is feed wasted?

Feed storage and distribution system

Feed bin management

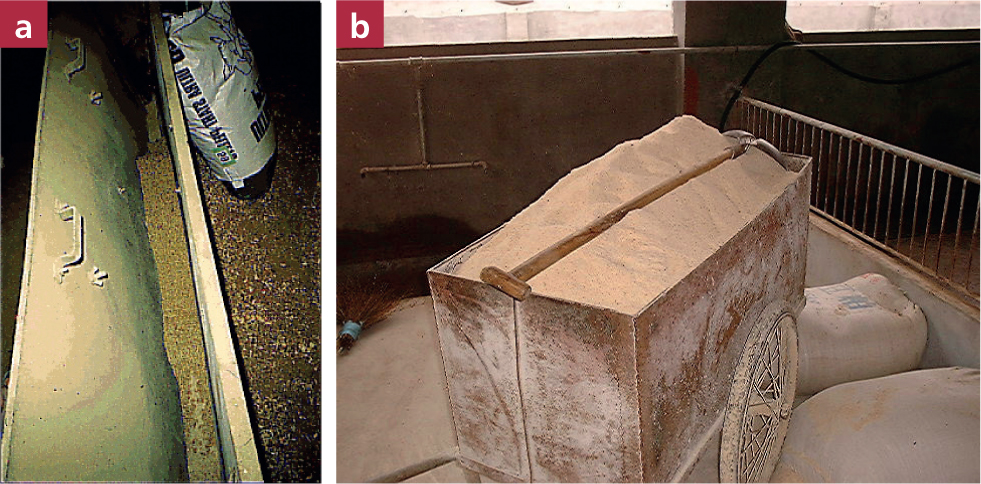

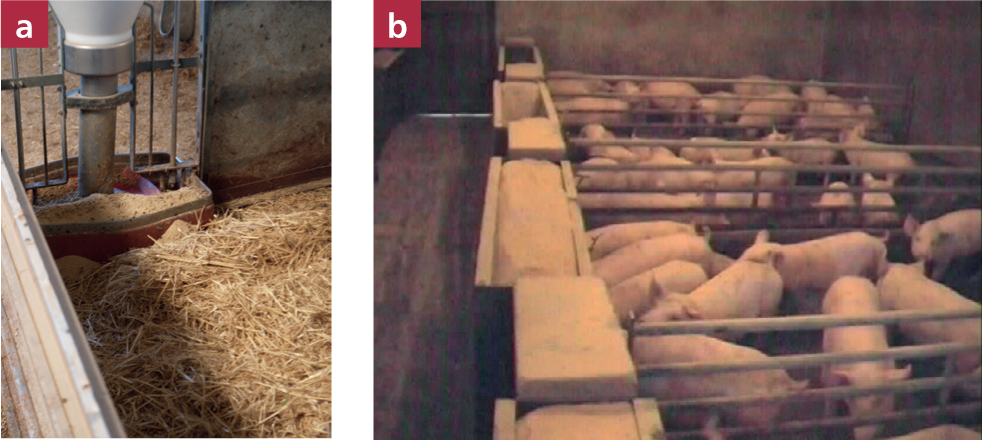

Avoid unnecessary waste while cleaning feed bins. Leaving spilt feed under the bin encourages rodents and vermin to the farm, which then consume feed (Figure 1). Routinely and regularly check the outside, the inside of feed bins and their associated pipe-work and augers.

Feed bin filling

When the feed bin is being filled, avoid all wasted and spilt feed. Once the feed had been delivered (Figure 2), ensure that the feed bins are properly re-sealed. Leaving feed bin lids open has resulted in over 30 tonnes of food being lost following a rain storm — the water causing the food to go mouldy (Carr personal experience).

Feed outage

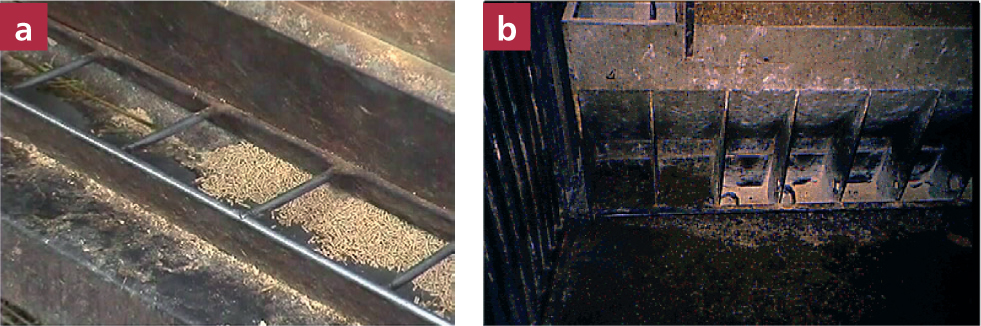

Manage and understand feed movement within a feed bin and ensure that feed outages do not occur (Figure 3). If a pig is without feed for 24 hours, a gastric ulcer may occur (Muirhead and Alexander, 2013). This results in poor feed digestion and leakage of blood, which has to be replaced, wasting nutrients. Pigs going without feed for more than 6 hours is extremely common on pig farms — a normal occurrence at least once in every batch of pigs produced.

Feed storage

Creep feed should not be exposed to temperature extremes — if it gets hot it will go stale more quickly and vitamins will degrade (Figure 4a). A typical example of this is storing creep feed within the nursery to make feeding easier for the stockperson.

Feed barrows

If feed is moved around the farm in barrows, ensure that the barrow is kept out of the rain and covered whenever not actually in use. Do not overfill feed barrows as this often leads to spillage of feed while moving the barrow around the farm (Figure 4b).

Wastage associated with medicated feed

Place medicated feed into the correct bin, ensure that all feed bins are numbered and that the delivery is recorded — label the bin accordingly (Figure 5).

Palatability

All feed that enters the farm should be tasted by the stockperson in charge of the area and the manager to ensure that feed palatability standards are being met. This should include wet feed ingredients. This has raised health and safety issues from various quarters. But we are producing a food product and all the ingredients going into the product should be safe to eat. If it is unsafe for the staff, why is it considered safe for the pigs?

High levels of medication may make the feed unpalatable. If there is any concern regarding palatability consider the use of sweeteners such as talins to mask the taste.

Feeder setup

Adequate feed space

To allow all the pigs to grow evenly it is essential to provide sufficient feeder space for all the pigs in the pen (Figure 6). This is particularly important in the first 3 days post-weaning. Plenty of feed spaces favour compromised, disadvantaged and the smaller pigs.

Note that the newly weaned pig requires three times more feed space than is required a week later. This is because newly weaned pigs feed as a group and do not understand the concept of ad lib feeders (Table 1).

Table 1. Feed space availability in a trough feeder

| Weight of pig (kg) | Trough/hopper length (mm)/pig | |

|---|---|---|

| Restrict fed | Ad Lib Fed | |

| 5 | 100 | 75 |

| 10 | 130 | 33 |

| 15 | 150 | 38 |

| 35 | 200 | 50 |

| 60 | 240 | 60 |

| 90 | 280 | 70 |

| 120 | 300 | 75 |

| Sow | 400 | N/a |

Feed distribution

Ensure that feed is distributed evenly along a feeder to minimise aggression and fighting at the feed space (Figure 7). This will also minimise uneven growth within a group of pigs. Do not place the feeder on a sloped floor.

Feeder in wrong position in the pen

When siting the feeder, consider the ease with which pigs can reach it (Figures 8 and 9). Feeders placed in cold corners will often become fouled with urine and faeces. Feeders placed too close to a divider or other obstacle, e.g. a drinker, may make that feeding place inaccessible. Pigs should not have reach or to jump up to gain access to the feeder as is sometimes seen when young pigs have to cope with raised feeders.

Feeders must be placed so that they can be easily examined

The stockperson must easily be able to examine the feeder for leakage, overflowing and soiling.

Feed and drinker position

Pigs like to drink shortly after feeding. If the drinkers are more than 2 metres from the feeder, they will walk between the feeder and drinker and carry food in their mouths and drop it as they go (Figure 10).

Ensure that the pigs do not have to cross the sleeping area to get from the feeder to the drinker.

Covering feeders

Uncovered feeders contribute up to 30% of the dust in the air and the feeder is exposed to rodents and possibly birds, which will eat the feed and soil the feed. All feeders should be covered. See through panels enable the feed level to be checked at a glance.

Management

Use the right feed at the right time

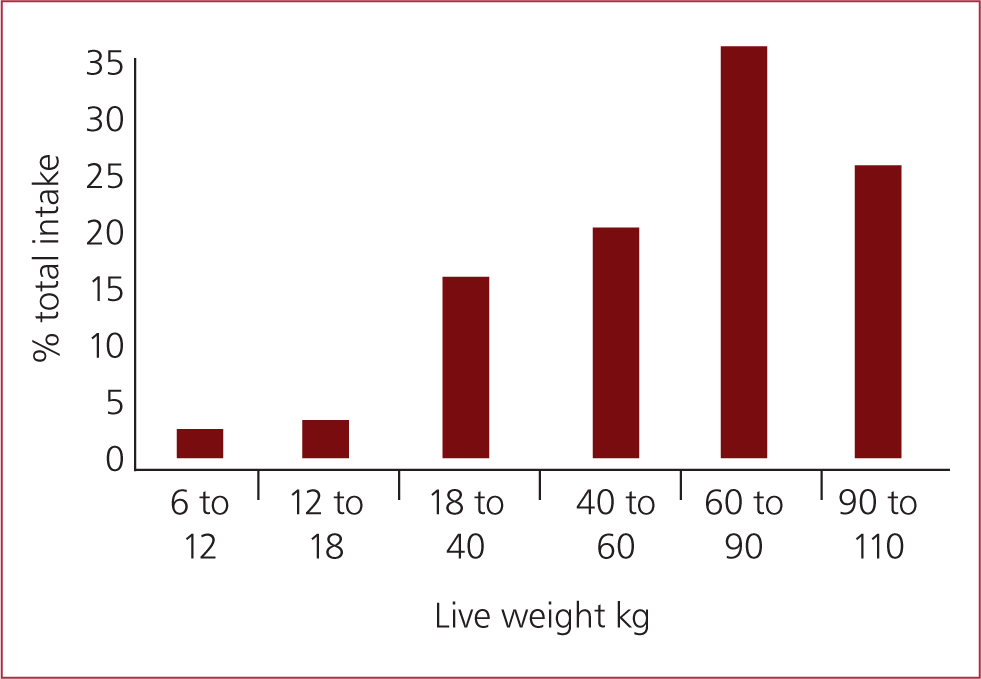

It is essential that pigs progressively move to the appropriate (cheaper) next diet as soon as possible while maximising their growth potential. Keeping pigs on the expensive early diets for longer than warranted, increases costs. This technique must not be used to compensate for the poor feed intake and growth in the first week post-weaning. Carry out regular feed budget audits to ensure that the farm is feeding appropriate levels of feed at every stage (Figure 11).

Use correct feed

High feed prices may tempt farmers to simplify and cheapen the feed, but growth and health are likely to be affected. Slowed growth will adversely affect pig flow and compromise all-in/all-out systems. Poorly formulated diets are more likely to result in diarrhoea, resulting in raw feed ingredients ending up on the floor.

Feed preparation

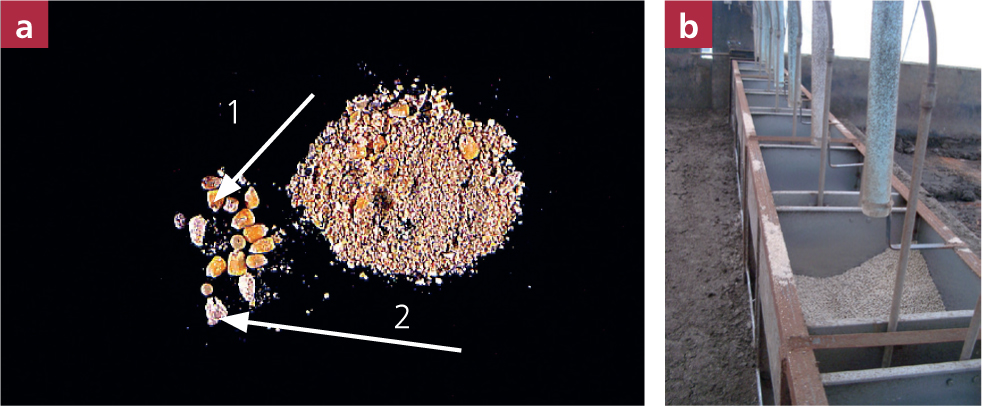

Feed that is incorrectly prepared will result in increased waste. Whole grains cannot be digested by the pig and are passed out whole and undigested (Figure 12a) — check rolling and crushing, grist size and dust levels.

Feed available when pigs enter a house

It is essential that pigs are fed the correct diet immediately when they enter the house. Requiring the pigs to eat up the last of the last group of pig's feed is not acceptable (Figure 12b) — it may contain the incorrect ingredients or medications, be stale and mouldy and soiled with rodent faeces and urine.

Feeding routines

Creep feeding in the farrowing house

Creep feeding can be beneficial provided that expensive creep feed is not wasted and soiled (Figure 13). Creep feed must be provided fresh at least three times daily — little and often. Start creep feeding after day 14 of age — this is based on the behaviour of outdoor pigs where piglets leave the nest around day 14 and start eating food.

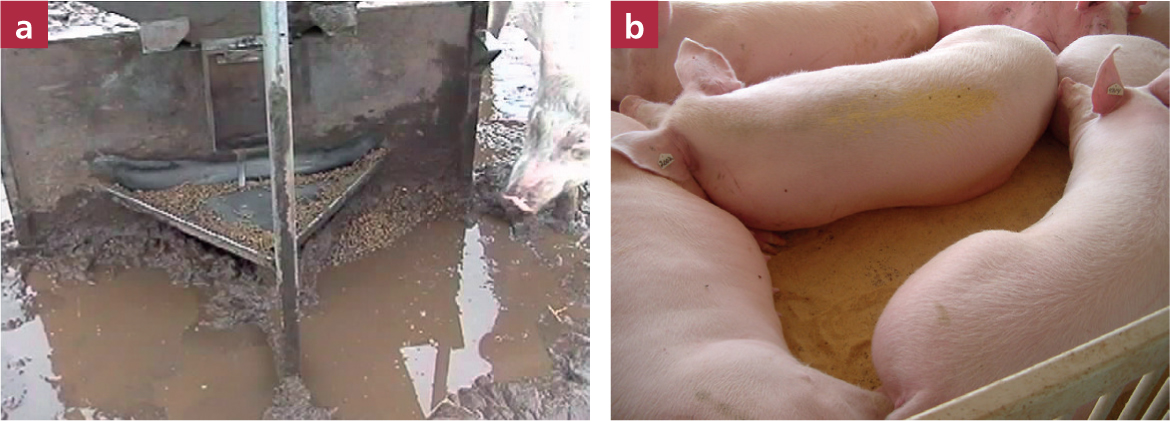

Adult pig feeding

The feeding routines practised in the farrowing, breeding and gestation areas can lead to enormous feed wastage (Figure 14 and 15). In the farrowing area attempting to step the feeding level up too quickly will result in loss of appetite in the lactating sow. She then fails to clean out the feed trough, resulting in spoilage, mould development and fly infestation. Feeding problems will result in water availability and affect milk supply to the piglets.

In the service area, sows in oestrus often do not eat, and feed remaining in the feed troughs may become unpalatable and wasted.

Dry sow feeding routines can be extremely careless, resulting in large amounts of feed being wasted on the floor. Combined with poor cleaning routines this feed soon becomes soiled. Over-feeding of the gestating sow is extremely common on pig farms (Carr, personal experience). This extra feed is wasted, does not benefit the growing piglets and reduces subsequent feed intake during lactation.

Feeder empty as the pigs leave the farm

Do not dispose of feed remaining in the feeder by pressure washing the feed down the slats. Careful management of the feeder in the finishing pen is an essential component of finishing.

Hospital pen feeders

The feeders in the hospital pen are often overfull and overrunning for only one or two pigs. This can result in tremendous wastage and attract vermin. Adjust feed in the hospital pen feeders according to the needs to the pigs (Figure 16).

Weekend feeding

It is extremely lazy to overfill feeders — especially in the newly weaned pens just to avoid having to feed at the weekend; this practice will result in wasted and soiled feed.

Feeder management

Holes in the feeder

It is imperative that all feeders are examined regularly — at least between batches. Where a feeder is found to have a hole, mend it or replace the feeder (Figure 17). Holes that occur over slats cost enormous amounts of money, where long-term feed leakage occurs without any obvious trace (Figure 18). Often holes in down-pipes and feed systems cause leakage out of sight. Even the feed bin can leak (Figure 19).

Feed quantity available

Feeders should be inspected and adjusted every day. This is one of the most important jobs for stockpeople. Feeders cannot be allowed to overrun on the pretext that it is to ensure pigs have ‘sufficient’ feed (Figure 20).

Feed efficiency can be maximised when pigs have to work for their feed. Placing less feed in the feeder by lowering the down-pipe into the feeder will reduce feed wastage and dust production although the feed auger may need to run more often. All stockpeople should understand in detail how a feeder works and how to adjust the feed availability (Figure 21). A feeder that is overrunning will also tend to make the feed powdery (Figure 22). This can result in feed intake refusal, increased dust contamination of the room, limited feed space and increased respiratory problems in the pigs.

Ignoring overrunning feeders

If stockpeople are in too much rush, they are likely to miss a feeder that is overrunning. One author (Carr) remembers (as a young pigman), an incident when the downpipe fell out of a feeder and the auger continued to discharge into the slurry pit over the week-end. The result was 30 tonnes of wasted feed as well as the time taken to dig out the slurry pit by a young stockperson who would never make that mistake again! Large quantities of feed can be wasted within hours this way, but feeders and feed systems should be equipped with suitable alarms to prevent this.

Water in the feeder

Any feeder with a self-contained water source has to be managed carefully to ensure that the it does not leak and fill the feeder, restricting feed access (Figure 23). Conversely, it is important to check that feed does not build up and limit water availability. Drinkers in feeders should be considered as ‘feed intake enhancers’ not as a primary water supply.

Soiling of the feed

Feeder placement is important as discussed above.

Effects of the weather and the feeder

It is important to minimise spoilage by bad weather, especially during rain-storms (Figure 24a). This applies to feed barrows and bagged feed areas too.

Floor feeding/feed as bedding

Floor feeding is wasteful and should be avoided (Figure 24b). Feed is an extremely expensive bedding material. It is not uncommon post-weaning to feed on the floor mat, but the provision of a simple inexpensive trough will not only reduce waste but also provide the stockperson with more detailed knowledge of feed consumption.

It is surprising the number of farms where feed is spread on the floor merely to indicate to the pigs where their ‘sleeping area’ is located. If this is the case, that is telling you that the pen layout needs to be reviewed so that it provides a draught free sleeping area to all pigs. To stimulate the memory of a sleeping area use farrowing drying powder used at birth to assist the piglets in localising the sleeping area.

Mouldy feed

Feed is easily soiled when water runs into a feeder, for example from a drip cooling system poorly managed (Figure 25). Wet feed can rapidly become mouldy and fly infested. Feed bins that are not sealed after filling or are sited where condensation can occur in the bin, cause feed wastage; mould leads to food refusal and ‘bridging’ in feed bins makes the risk of mycotoxin formation much greater. Feed bins placed directly in front of outlet fans can be problematic.

Farrowing and gestation sows

Lactating sow food is particularly prone to soiling through overfeeding.

Rodent and vermin control

Birds, mice and rats can consume vast quantities of pig feed when they have the opportunity (Figure 26). Their faeces and urine contribute to the soiling, spoilage and palatability problems (Figure 27). Feeders should be covered to reduce access to vermin. Buildings should be bird-proofed. This will also reduce the risk of introducing novel pathogens to the farm.

Food conversion ratio (FCR) could be reduced by as much as 0.3 (3.0 to 2.7 — 30–100 kg liveweight) in open fronted buildings and tents by covering feeders! On outdoor units, gulls and other birds swoop down and take several pellets at one time; sows will often stand to one side while the birds eat (Carr personal experience).

An adult rat eats 15 g a day — with a 1000 rats on the farm this is nearly 5 tonnes per year (John Hopkins University, n.d.).

A gull eats 100 g a day — with a 100 gulls eating their ration a day this is 3.7 tonnes per year (Wickstrom, n.d.).

Avoid feeding unnecessary animals

Non pregnant sows

Sows remaining on farm for 6 weeks post-mating should be pregnant. A sow that is discovered not pregnant in week 16 of ‘gestation’ has consumed 175 kg (2.5 x 7 x 10) of feed since mating (Muirhead and Alexander, 2013). On many farms, this can be as many as 7% of sows. On a 250 sow unit this would account for 3 tonnes of sow feed a year.

Cull sows

Once the decision to cull a sow is made, ensure that she is culled as soon as possible. Cull sows eat at least 2.5 kg a day. But ensure that the breeding and pregnancy target is met before culling sows.

Review parity structure of the farm

Piglets born to a parity 1 sows (gilt litter) take 5 to 10 days longer to finish (Miller et al, 2008) (compared with multiparity sows) and this is an extra 20 kg of feed! The more parity 1 in a batch the slower the batch will finish and the more food the batch will eat.

Feeding finishing pigs prior to slaughter

To feed a pig immediately prior to slaughter wastes 2.5 kg per pig sold. In addition, it can make the journey to the slaughter-house extremely unpleasant for the pigs by inducing vomiting and travel sickness.

Overweight finishing pigs

Finishing pigs must be weighed and sold into the slaughterhouse matrix. ‘Outliers’ are extremely expensive. At 120 kg with a P2 of 16 mm not only have they eaten you out of house and home, they will incur a penalty at the slaughterhouse, further reducing any return. The impact of COVID on slaughterhouses and closures can and does cause chaos by removing availability of shackles forcing farms to hold pigs back.

Review culling of runt pigs

Pigs that are born small and or weaned light should be carefully reviewed (Figure 28). 90% of pigs born below 800 g die before reaching slaughter weight. Small weak born piglets have an FCR rate 3.5 to 4.0 instead of 2.4 to 2.6 (Carr personal findings).

Sick pigs

Review the pigs in the hospital area. Pigs with rectal strictures are common and often have ravenous appetites, but will never be suitable for marketing (Figure 29). In the hospital area tag all pigs with an individual number and review their progress after 7 and 14 days post entry.

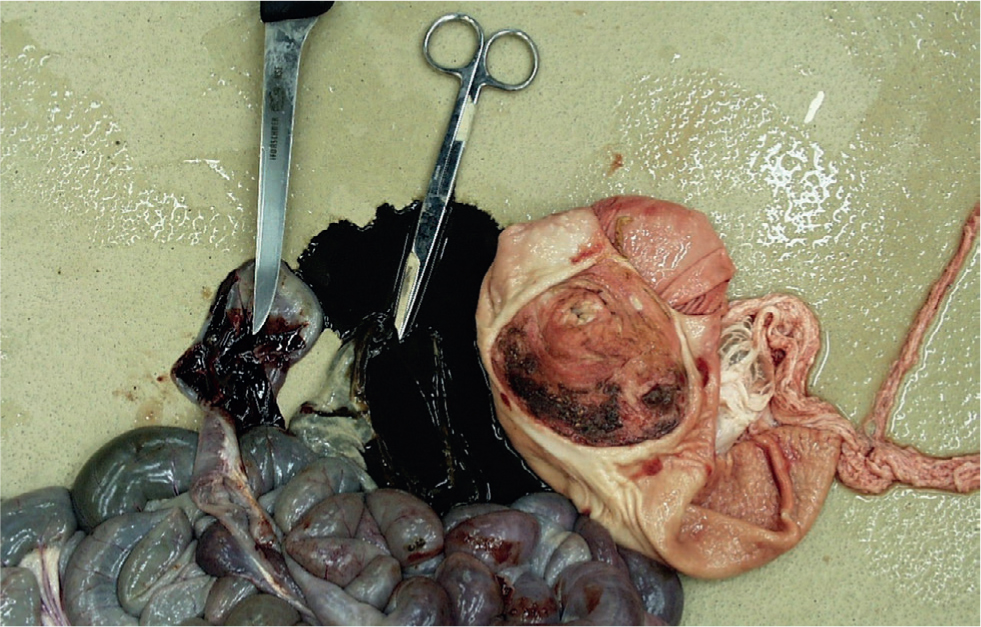

Ileitis and chronic diseases

Ileitis (Figure 30) associated with the bacterium Lawsonia intracellularis causes chronic feed wastage as it increases the thickness of the gut, resulting in less digested feed being absorbed. This may result in a loss of growth of 40 g a day, which at a FCR of 3 is 120g a day of extra feed eaten. Review the impact of ileitis on the farm. Swine dysentery (Brachyspira hyodysenteriae) can cause ruinous impact on feed wastage and usage.

Partial and full depopulation?

If the disease problems on the farm become chronic (long-standing), consider a partial or full depopulation to allow for full cleaning and refurbishment of the farm. A reduction in 0.5 FCR is not uncommon on farms post-partial depopulation. Animals living with a heavy pathogen load in their environment have to divert nutrients from growth to immunity, which is costly in terms of energy.

Gastric ulcer

Gastric ulceration occurs because the pig fails to eat over a 24 hour period (Figure 31). If the feed is very fine (<700 m) the feed will then aggravate any existing gastric ulcer. Gastric ulcers result in feed wastage because feed intake and digestion are compromised and chronic anaemia results. These pigs are weakened and prone to secondary infections and bullying by other pigs.

Avoid wasted energy through unnecessary activity

Wet bedded areas

If the bedding area is very wet and boggy, pigs struggle to move around the pen (Figure 32). This can be a particular problem in deep straw bedded systems and outdoor open fronted huts and may add 0.2 FCR onto the feed bill.

Misplaced drinkers

If the drinkers are sited far from the feeders the energetic cost of travelling to and fro is exacerbated.

Air temperature and comfort

Ensure that you keep pigs within their thermal comfort zone. If the pigs' environment is too cold, energy will be consumed to help keep the pig warm. If the pigs are too hot, feed consumption and growth will fall and extra effort will be expended to pant to help the pig lose heat (Figure 33). Farrowing areas should be fed at cooler times of the day.

How much is feed wastage costing you?

The impact of feed wastage

The cost of feed wastage is demonstrated in Table 2.

Table 2. The effect of actual feed usage at various levels of feed wastage

| Age (weeks) | Gain (g/day) | FCR idealised | Consumption (g/day) | Actual feed usage feed wastage (%) | ||

|---|---|---|---|---|---|---|

| 2 | 10 | 15 | ||||

| 4 | 215 | 1 | 215 | 219 | 237 | 247 |

| 6 | 395 | 1.2 | 474 | 483 | 521 | 545 |

| 8 | 630 | 1.4 | 882 | 900 | 970 | 1014 |

| 10 | 660 | 1.6 | 1056 | 1077 | 1162 | 1214 |

| 12 | 715 | 1.8 | 1287 | 1313 | 1416 | 1480 |

| 14 | 800 | 2.4 | 1920 | 1958 | 2112 | 2208 |

| 16 | 965 | 2.6 | 2509 | 2559 | 2760 | 2885 |

| 18 | 1000 | 2.9 | 2900 | 2958 | 3190 | 3335 |

| 20 | 1100 | 3 | 3300 | 3366 | 3630 | 3795 |

| 22 | 1100 | 3.2 | 3520 | 3590 | 3872 | 4048 |

| Adult | 4 | 3000 | 3060 | 3300 | 3450 | |

| 8.2 tonnes per sow per year with an average price of £315 per tonne farrow to finish at 87 kg dwt | Per kg deadweight | £0.02 | £0.11 | £0.17 | ||

| Per pig sold | £1.97 | £9.86 | £14.78 | |||

| Per year | £11,686 | £58,429 | £87,644 | |||

| Feed wastage estimation of cost | ||||||

| Farrowing places per batch 10 | Batch time 1 week | |||||

| This is about a 236 sow unit | ||||||

Conclusion

At any time it is vital to minimise feed wastage. As feed is the number one cost in the production of livestock it is essential that the veterinarian is aware of potential areas where wasted feed can be minimised. As the pig's and farming carbon footprint becomes more significant, minimising feed wastage is significant in the sustainability of pig farming.

KEY POINTS

- Feed wastage can account for 10% of the total cost of pig production.

- Feed wastage occurs through mechanical and biological reasons.

- The veterinarian should examine all the feeders in a production system for holes.

- Rats and birds eat considerable amount of pig feed.

- Veterinarians need to advise clients when it is not possible to reach an economic return from compromised production animals.