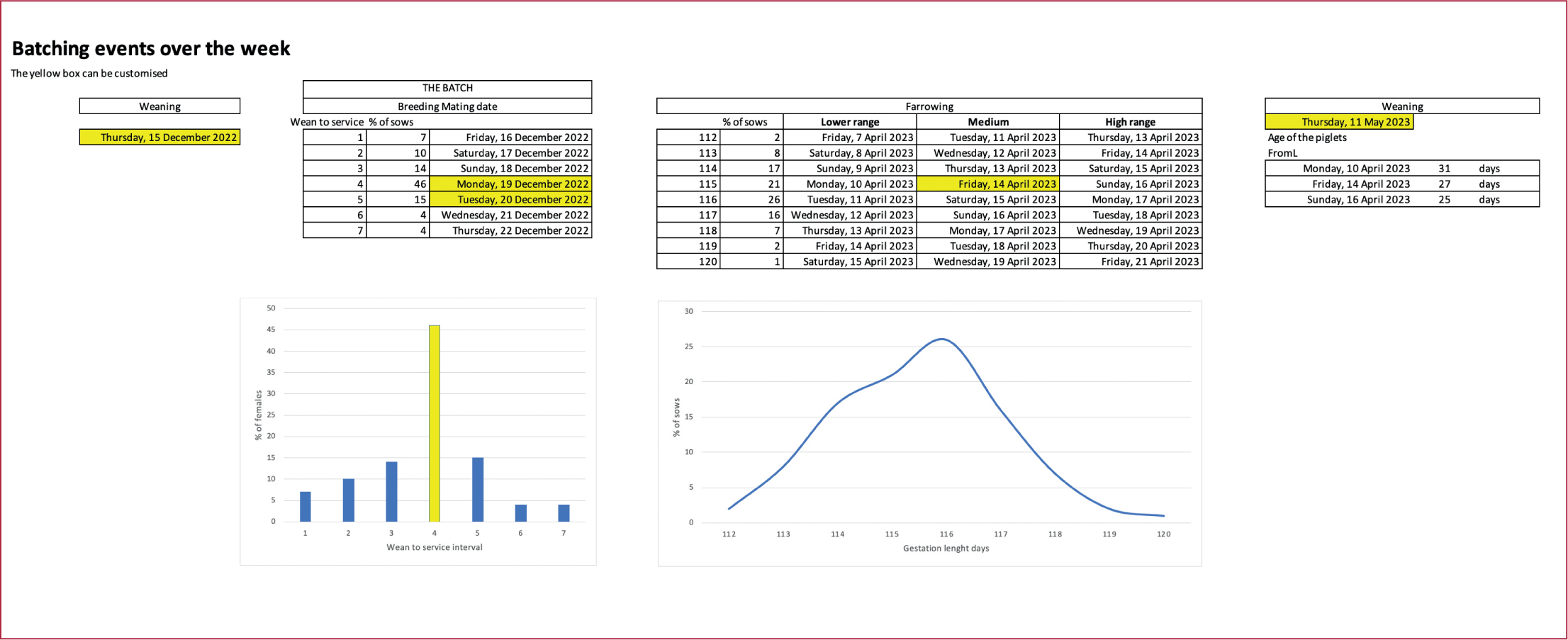

If you want to practice ‘all-in/all-out’ pig flow on a pig farm, by definition you need to batch. A batch is defined as the output from a group of sows from one weaning to another. In the simplest model, a pig farm will wean sows weekly (Figure 1), traditionally on Thursdays, so that a week's batch (7 day batch) starts the day after weaning and includes all the female pigs bred from day 1 (Friday in this example) to day 7 (the next Thursday). Then the next batch opens. Note that often the farm software accounts package uses Monday to Monday, but then the batch that is served does not correspond with the batch that farrows! This results in the mated gilts being in the wrong ‘group’ and reduces weaning age.

The batch number is maintained all the way to slaughter. To make things easy, the authors use the ‘weeknum()’ function in Microsoft Excel to define the batch number based on the first day of the batch.

The dynamics of time within the batch

With the batch concept in place the major events on a pig farm can be regimented into:

- Weaning day: Thursday

- Wean to service interval is 4 to 5 days (Carr, 2008), so the peak service period for weaned sows is Monday and Tuesday (Figure 2)

- Farrowing is said to occur 115 days post-service (Muirhead and Alexander, 2013)

- Therefore, Friday and over the weekend, the main part of the batch will farrow (some modern genotypes tend towards longer gestation periods (Pig333, 2021)) (Figure 3).

Figure 4 shows the normal distribution of biology expectations within the batch.

Batching options

There are a few obvious options for adjusting batching time length as determined by the required average weaning age of the batch of pig and the gestation length, which is essentially fixed.

Shaded red (Table 1) indicates that the batching system is possible and fits into a 52-week year for 3- and 4-week weaning systems. Note the biology of a 5-week batching, 4-week weaning system involve a skip week but is still possible (Table 1).

Table 1. Simple batching options

| Batch length time (weeks) | ||||||

|---|---|---|---|---|---|---|

| Weaning age | 0.5 | 1 | 2 | 3 | 4 | 5 |

| 20 days | ||||||

| 27 days | ||||||

Within the UK and EU, as weaning below 28 days can only occur if the pigs are placed in a specialised nursery (The welfare of farmed animals' amendment regulations 2003 part V section 46 and 47), therefore batching options based on 27 days are possible. If 2- and 4-week batching systems are chosen with 4 week batching these are more complex involving lost skip weeks and are not considered in this discussion (Christiansen, 2010).

Translating this dynamic into the yearly workload

The following calendar of events work from the first Tuesday of the year (the breeding day for batch 1).

Weekly batching system

In a weekly batching system, every week has a batch of sows to wean, another batch to bred and another batch to farrow (Table 2).

Table 2. One week batching calendar of events over a year

Two different batches (1 and 10) are coloured to illustrate the movement of the batch over the year (Table 2).

Three-week batching systems (Thursday weaning)

In a 3-week batching system, one batch of sows is weaned, the following week a batch is served and the following week a batch farrows (Table 3).

Table 3. Three week batching calendar of events over a year

Five-week batching system (Thursday weaning)

In five-week batching systems (Table 4), the sows are weaned in one week, the following week a batch is bred and in that same week the next batch farrows. Then for 3 weeks, there is no specific event. Each batch is coloured to indicate its flow over the year.

Table 4. Five-week batching calendar of events over a year. Each batch is coloured to indicate its flow over the year.

Note that with the 5-week batching system, after each 4 batches there is a skip week. This is illustrated by the black cell in Table 4.

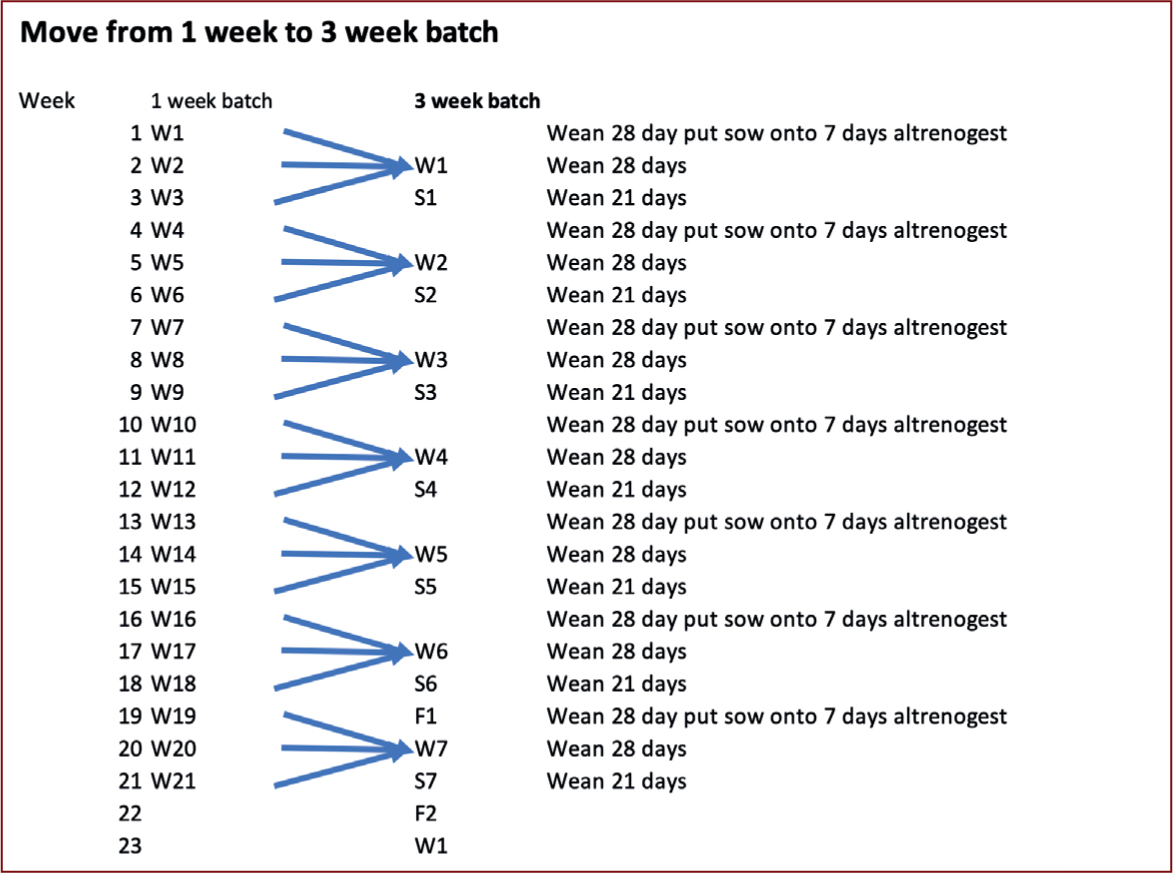

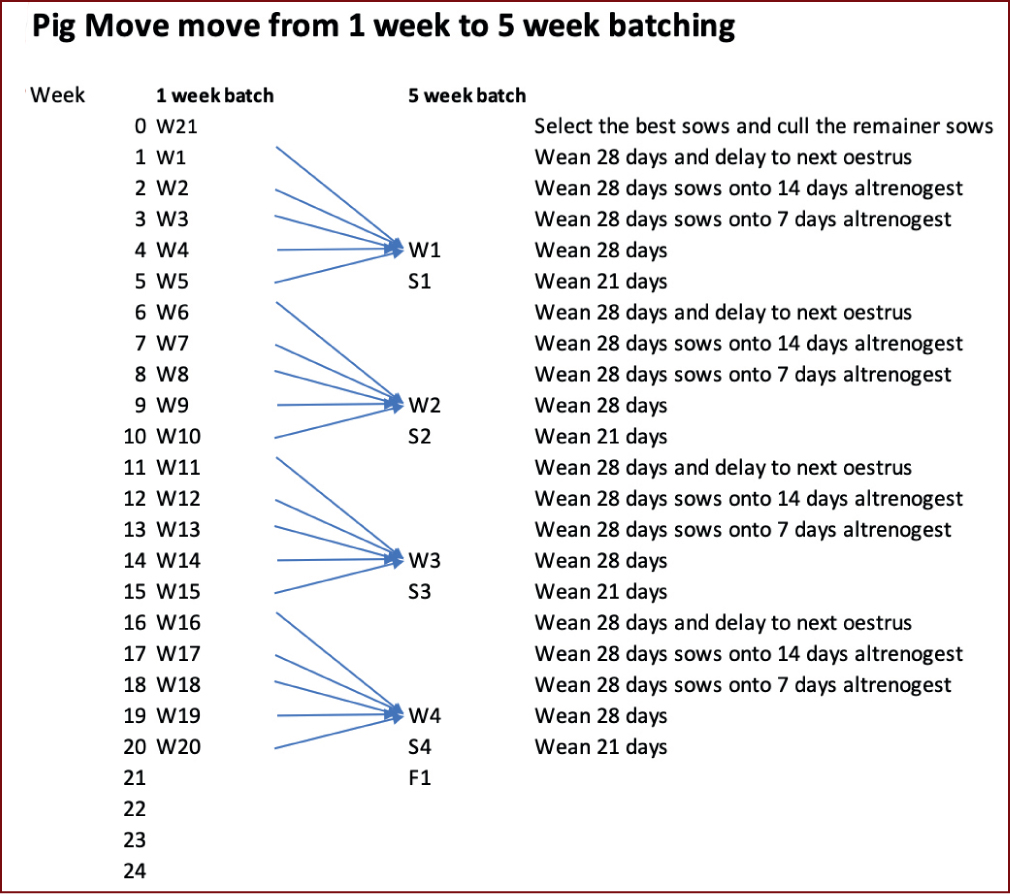

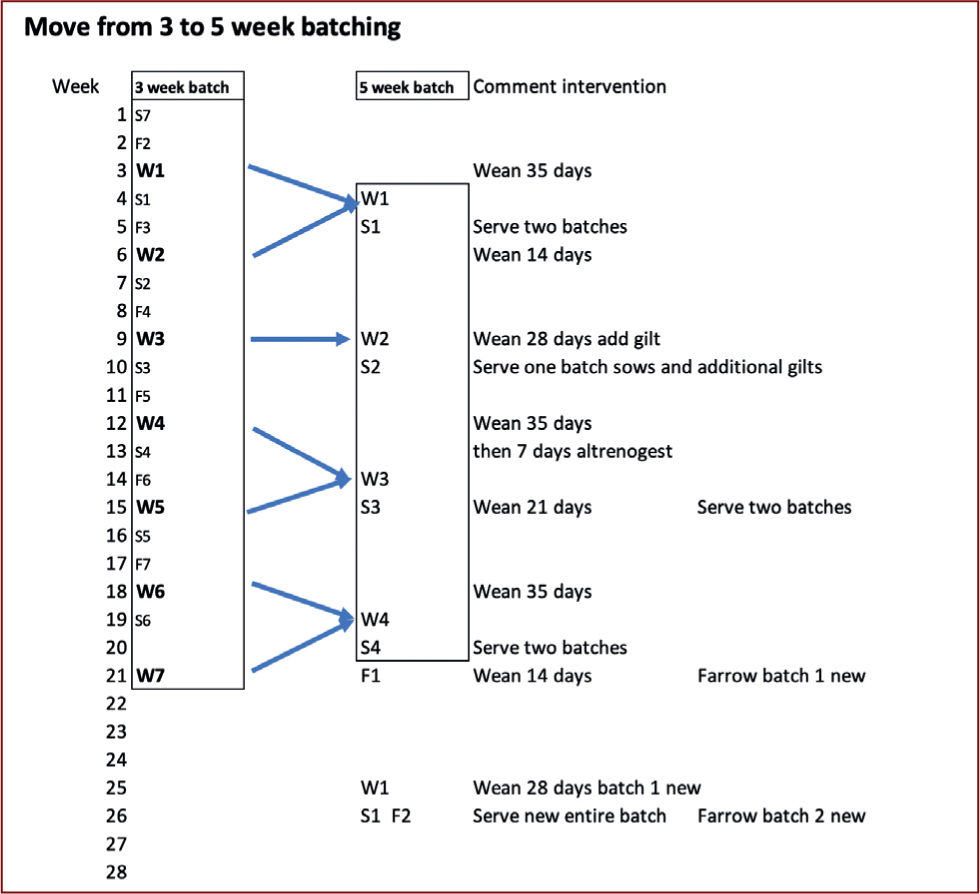

Moving from weekly systems to a 3- or 5-week batching system

With imagination, the farm health team may be able to design a number of practical systems to control the reproductive biology of sows and modify the batching system.

The authors' preferred method of controlling the natural oestrus cycle to evoke a change is to deploy oral altrenogest medication (Carr and Sperling, 2022). Sows are either ‘held’ in suspended animation by the medication, or weaned early to form each of the new batch timings (service weeks).

The early weaning of pigs is deemed acceptable as the move is in the long term welfare interest of the farm and it is a temporary measure only.

Benefits of batching

To achieve all-in/all-out the farm must efficiently batch. Each batch must be considered as a unit. Batching offers enhancement in the health and pathogen control on the farm (Carr, 1999). Batching and actually achieving all-in/all-out has reduced medicine usage of farms by 75% (Carr, 1999). Growth rates have been reduced by 2 weeks to 115 kg liveweight. Equipment such as needles and syringes can be better accounted for, reducing lost or broken needles. The larger groups allow for better utilisation of medicines – for example the batch can be designed to ensure whole bottles of vaccines are utilised, reducing medicine waste (Carr, 1999).

It also has significant social impact on the farm by providing convenient disciplines for the farm staff to follow. On many farms, it has provided the farmer's with their first family holiday in decades.

Having more disciplined workloads allow the farm to target repairs. There may be times when the farm team has ‘little to do’, for example one week there is only breeding. The whole staff team can then work to make repairs. This improves not only teamwork but also health and safety around the work schedule. With some batching options it may be possible to move expertise between different farms within a company.

Batching also helps the farm health team to continue to provide excellent health advice and efficient monitoring of the farm's performance to demonstrate that the health advice is actually cost effective. Having specific set targets and laying down guidance in achievements at all stages of production, makes it easier to manage and constantly review the performance of the farm. This reduces the variation on a farm. A farm not batching often has a 40–60% variance around the mean production, whereas with batching, the farm can reduce this variance to 10%. Reduction in variation may also mean achieving full loads of pigs for transport and this can reduce fuel costs. Such advantages may make significant changes to a sustainability exercise and reduce carbon emissions from the farm.

In some batching models there is an increase in the number of animals in a batch, if multiple weeks are batched together. This may increase the number of smaller, compromised animals in any one batch. This is actually an advantage. If in a weekly batch there were 10 small pigs, these few pigs may have been lost in the system. With the same farm changed to a five-week batch model, this becomes 50 small, compromised pigs. This then is a whole pen or even room. Therefore, dedicated expertise can be focused on these compromised pigs, increasing their performance, survivability and welfare.

Summary

These combined benefits all boost the wellbeing and welfare of the pigs and farm staff. The farm can control the stocking densities of and make fine adjustments for any seasonal impact. This allows the farm to ‘farm’ to legal and advised guidelines.

KEY POINTS

- All-in/all-out is achieved through batch management.

- Batching the farm can enhance animal welfare and reduce antimicrobial use.

- Batching options allow for beneficial societal changes in the workload on a farm.

- The move to different batching time systems can be challenging for the whole farm team and the veterinary surgeon can take a lead role in supporting the team.

- Legal challenges in farming systems can be disciplined using batching systems.